What Copper Rock Crusher For Sinter Fines

Sinter crushers Welding Alloys

2023年2月1日 Sinter Stars, Grizzly Bars, and Crash Decks are crucial parts subject to high temperature, impact and abrasion during the sintering process. Our experts have spent the last 20 years developing the unique 3D-Carb ™ Technology to hardface wear parts used

Choosing the right crusher Buying Guides DirectIndustry

2019年1月29日 Metso cone crusher. Cone crushers, also known as conical crushers, break rock between an eccentric rotating head and a bowl.The rotating head is covered

Type of crushers and their difference JXSC Mining

2019年12月10日 The double roll crusher is the most common rock stone crushing machine. Its crushing ratio is usually lower than in other crushers, so it’s suitable for fine

进一步探索

5 Types Of Stone Crushers Application and MaintenanceCharacteristics and Comparison of Four Types of Jaw Crush根据热度为您推荐•反馈

Types of Rock Crushers Quarry Crushing

1 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone,

Which Crusher Is Suitable for Your Hard Rock? Fote

2023年2月15日 Protodyakonov rock classification is based on Protodyakonov scale to classify the hard rock and soft rock. f = 15-20: Extremely strong rocks, such as very

Sintering: A Step Between Mining Iron Ore and Steelmaking

2019年6月11日 Sinter quality begins with the mined iron ore and the proper selection and mixing of the raw materials. Inhomogeneous raw mix can affect permeability and cause

mill/sbm roll crusher for iron sinter.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

What Copper Rock Crusher For Sinter Fines

Mini Rock Crusher 911metallurgist. The 1″ X 2″ 911MPEJAC12 Small Rock Crusher is designed to finely crush rock and stone like aggregates or your favourite ore type (gold,

closed circuit crushing systems what iron ore crusher for

PRE-FEASIBILITY REPORT PROPOSED 1.30 MTPA IRON 2016-8-5 1.30 MTPA Iron Ore Beneficiation plant 0.80 MTPA Jigging plant for sinter feed Low grade Iron Ore fines

sbm/sbm iron ore pricing fines sinter concentrate.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

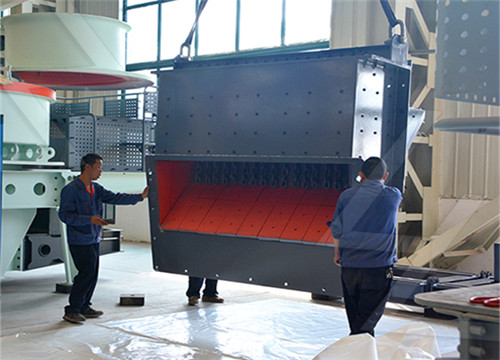

Understanding Sinter and Sinter Plant

2015年3月15日 The fines removed by the hot screens are conveyed to the return fines bin. Cooling of the sinter below 150 deg C, so that it can be handled on conveyor belts, is an important part of the operation. Sinter

Types of Rock Crushers Quarry Crushing

1 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary

Copper Mining and Processing: Processing Copper Ores

1 Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday use.The most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and

Sinter Plant Presentation (Sinter Operation) [PDF

2015年10月13日 For Example : BF Iron ore fines, Sinter fines, Pellet fines, Coke finesFlue Dust SMS Slag, Gas cleaning plant dust Sponge Iron Plant SIP Sludge, Iron Ore fines Rolling Mill Mill scale Iron Ore mines Iron Ore fines 198 Sq. mtIgnition Furnace : 2Row vertical Burners (12+11)Hot Sinter Crusher : 3500 LongX 1700 DiaCircular Cooler : 228

sbmchina/sbm sintering manganese ore.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

sbm/sbm price of sinter crusher sintering 24.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Sintering plant at a glance SlideShare

2014年10月27日 1 SINTERING PLANT . Sintering plant at a glance 1. 1 SINTERING PLANT 2. 2 DEFINITION OF SINTERING Sintering is a process of agglomeration of fine mineral particles into a porous and

Sintering: A Step Between Mining Iron Ore and Steelmaking

2019年6月11日 Sinter quality begins with the mined iron ore and the proper selection and mixing of the raw materials. Inhomogeneous raw mix can affect permeability and cause an increase in fuel consumption. During the iron ore sintering process in iron and steel manufacturing, an online analyzer can be used to determine the elemental composition

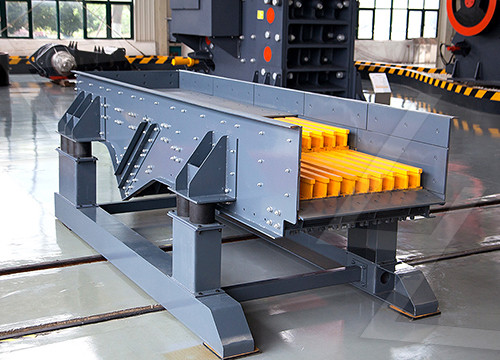

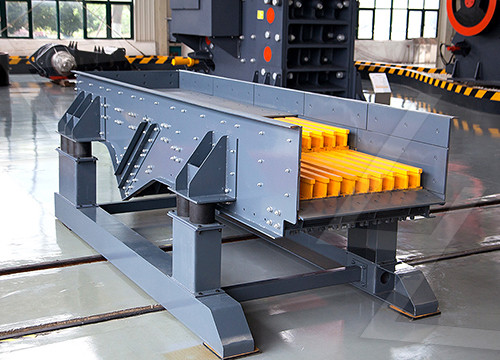

FAQ: Tips and Techniques for using Crusher fines surfacing

For use in trail surfacing, the material should be composed of irregular angular particles that interlock and bind into a firm matrix. The rock particles should range in size from dust to 3/8 inch. Gravel and crusher fines differ from one another in that gravel is screened to remove the fines which contain the natural binders/cements.

Sinter crushers Welding Alloys

2023年2月1日 Sinter Stars, Grizzly Bars, and Crash Decks are crucial parts subject to high temperature, impact and abrasion during the sintering process. Our experts have spent the last 20 years developing the unique 3D-Carb ™ Technology to hardface wear parts used in the sintering process.. Wear on sinter parts can result in decreased sinter quality,

(PDF) Iron Ore Sintering: Process ResearchGate

2017年2月16日 Carmen González-Gasca. Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents and solid fuel (coke

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

Types of Crushers: What You Need to Know Machinery

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.

sbmchina/sbm sintering manganese ore.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Crushing Products Size and Shape -What to

2016年2月26日 The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or

Rock Crusher JawCone Rock Crushing

Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, building material, road, railway, water conservancy, chemical industry, and so on. PE400-600-jaw-crusher.

FAQ: Tips and Techniques for using Crusher fines surfacing

For use in trail surfacing, the material should be composed of irregular angular particles that interlock and bind into a firm matrix. The rock particles should range in size from dust to 3/8 inch. Gravel and crusher fines differ from one another in that gravel is screened to remove the fines which contain the natural binders/cements.

DIY Crusher Fines Garden Path Plant Addicts

2020年12月10日 Pile of crusher fines ready to dump and spread over new fabric.Crusher fines are made of tinier particles and dust, so after you level and tamp them down, the surface evens out and compacts, forming a hard layer that feels more like concrete than rock, but maintaining a rocky, natural appearance. Spending 2 to 3 months cleaning

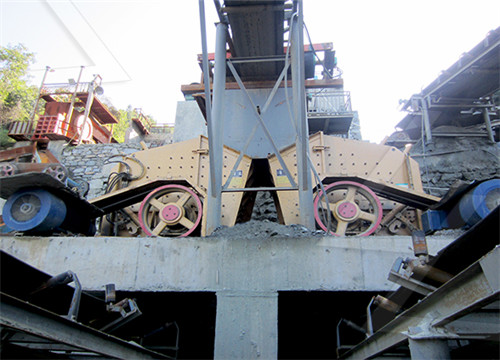

Hot Sinter Crusher

2021年9月16日 Ore Sintering An Overview Sciencedirect Topics. the hot crushed sinter is sometimes screened to remove hot return fines and then discharged onto a straight or annular cooler which cools the sinter down to about 150 c after the cooler coarse sinter particles of larger than 5075 mm are usually crushed by a secondary crusher and