Mining Mill Iron Ore Pelletization

Iron ore pelletization ScienceDirect

2022年1月1日 The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price. Binders accomplish two very

进一步探索

(PDF) Iron ore pelletization ResearchGateIron Ore Pelletization FEECO International Inc.Iron ore pelletization ScienceDirect根据热度为您推荐•反馈

Pelletization Metso Outotec

Pelletization is the process of transforming iron ore fines into spherical pellets through agglomeration and induration. These pellets are then used as feed to a blast furnace or

(PDF) Iron ore pelletization ResearchGate

2015年12月31日 Iron ore pelletization. A brief introduction to recent developments in iron ore pelletizing is provided in this chapter, including

(PDF) Iron Ore Pelletizing Process: An Overview

2018年7月11日 The iron ore is mined mostly from open pit deposits through mining operations and the raw. known as iron ore pellets [2].

Iron Ore Pelletizing Process: An Overview

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Iron Ore Pelletization FEECO International Inc.

Pelletizing, or balling, carried out through either a disc pelletizer or rotary drum, is a key part of efficiently and sustainably producing steel from iron ore fines of varying sources.

Fine Dry Grinding of Iron Ore for Pelletizing

2019年6月20日 When dry grinding is selected the moisture required for pelletizing must be provided either by wetting the ore and mixing prior to balling or by adding all the moisture in the balling device. To date only

pelletizing of iron ore kurt meyer pdf Grinding Mill China

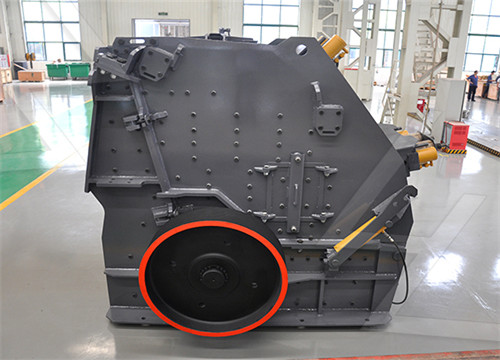

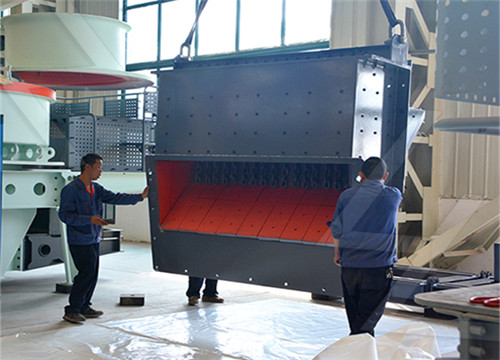

The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are Jaw Crusher, Cone Crusher, Hammer Crusher and Ball

flow diagram for iron ore beneficiation with pelletization

Mining ?granite quarry organisation chart ?soil crushing and sieving machine ?15 rock ore crusher pulverizer / 2 hp motor ?parker jaw crusher parts in the usa or canada ?rock

Iron ore pelletization ScienceDirect

2022年1月1日 The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price. Binders accomplish two very important functions in iron ore pelletization: •.

PyroGenesis Provides Update on its Iron Ore Pelletization

2023年1月26日 Pelletization is the process in which iron ore is concentrated before shipment, thus significantly reducing the cost of transportation, and providing an essential feedstock for blast furnaces.

Iron Ore 1st Edition

2023年3月2日 Description. Iron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as

[PDF] Mine/Mill production planning based on a

The Pau Branco mine supplies two blast furnaces with iron ore lumps, and currently, charcoal consumption for pig iron production accounts for 47% of the blast furnaces' operational cost. A geometallurgical model is presented to support an economic study considering reserve volumes, product quality, and operational costs based on the

Materials Free Full-Text Study of an Organic Binder of

The aim of this study was to investigate the properties of an organic binder used in cold-bonded briquettes (CBBs) prepared from two different iron bearing materials. The applied binder is a type of starch as indicated by chemical analysis, iodine-starch staining and Fourier transform infrared analyses. Thermogravimetric differential scanning calorimetry

A Study on Removal of Clay Minerals from Barbil Region

The presence of appreciable quantity of clay mineral in Indian hematite ore needs an attrition technique using screw scrubber in the beneficiation circuit to remove the ultrafine clays and avoid downstream operational problems. Spectroscopic analysis revealed that iron ore samples obtained from the Barbil region of Odisha contain a high amount of silica and

Pelletization of iron ore fines with parameter

2019年1月18日 The -3mesh ROM iron ore sample, collected from Barsua iron ore mines of Odisha, was crushed in a dodge type jaw crusher. The crushed product was passed through a roll crusher, which was then ground to 100% passing 200mesh in a ball mill. This head sample was used for characterization. Beneficiation studies were carried out after grinding

Newgate Global Resources LinkedIn

5 小时之 About us. Newgate Global Resources LLC specializes in trading Iron Ore, Steel, and Non-ferrous products. We provide supply chain management solutions from our offices in New York, the Midwest, and

sbmchina/sbm underground mineral crushing

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Iron Ore Pelletizing Plant Iron Ore Pelletizing Pellet

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is mainly driven by the growing need for steel in end-use industries such as the automobile industry, shipbuilding industry, construction

New Paradigms for Iron Ore Pelletization SpringerLink

2018年8月19日 Abstract. In recent years, there have been several efforts to develop binder mixtures for iron ore pelletization . Some efforts have been fruitful, while others have encountered failure. For example, adding corn starch to bentonite is effective, while adding fly ash to bentonite is not. When binders are made with fly ash, a pozzolanic reaction

PyroGenesis Provides Update on its Iron Ore Pelletization

2020年11月13日 For background, pelletization is the process in which iron ore is concentrated before shipment, thus significantly reducing the cost of transportation, and providing a required feedstock for blast

[PDF] Mine/Mill production planning based on a

The Pau Branco mine supplies two blast furnaces with iron ore lumps, and currently, charcoal consumption for pig iron production accounts for 47% of the blast furnaces' operational cost. A geometallurgical model is presented to support an economic study considering reserve volumes, product quality, and operational costs based on the

Materials Free Full-Text Study of an Organic Binder of

The aim of this study was to investigate the properties of an organic binder used in cold-bonded briquettes (CBBs) prepared from two different iron bearing materials. The applied binder is a type of starch as indicated by chemical analysis, iodine-starch staining and Fourier transform infrared analyses. Thermogravimetric differential scanning calorimetry

A Study on Removal of Clay Minerals from Barbil Region

The presence of appreciable quantity of clay mineral in Indian hematite ore needs an attrition technique using screw scrubber in the beneficiation circuit to remove the ultrafine clays and avoid downstream operational problems. Spectroscopic analysis revealed that iron ore samples obtained from the Barbil region of Odisha contain a high amount of silica and

Newgate Global Resources LinkedIn

5 小时之 About us. Newgate Global Resources LLC specializes in trading Iron Ore, Steel, and Non-ferrous products. We provide supply chain management solutions from our offices in New York, the Midwest, and

Iron Ore Pelletizing Plant Iron Ore Pelletizing Pellet

The iron ore pellet market is expected to achieve stable growth from 2021 to 2028. According to the analysis of Data Bridge Market Research, the market is growing at a CAGR of 3.6%. The iron ore pellet market is mainly driven by the growing need for steel in end-use industries such as the automobile industry, shipbuilding industry, construction

sbmchina/sbm underground mineral crushing

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Lower Steel Emissions Shows Opportunity for Iron Ore

Iron ore producers employ either a balling disc (disc pelletizer) or balling drum (agglomeration drum) to pelletize fines into high-quality iron ore pellets. Steel Mill Byproduct Recovery. The recovery of byproducts yielded during the steelmaking process will also become more important in the push for a circular economy.