Mining Good Sf Size Indutrial Silver Flotation Machine

Flotation Machines Mineral Processing MachineSolutions

1. Good mixing function. a qualified flotation machine should mix the slurry uniformly and maintain the particles especially the target mineral particle

SF Flotation Machine Yantai Rhyther Mining

SF Flotation Machine |. 【Introduction】: SF flotation cell is a mechanical agitation type flotation equipment with self-slurry suction and self-air suction. 【Volume】: 0.37~20m3. 【Improvement】: Both sides of the

Flotation Machines Mineral ProcessingMetallurgy

2015年6月22日Industrial flotation machines can be divided into four classes: mechanical. pneumatic. froth separation. column. air-lift.

SF Flotation machine Yantai Jinpeng Mining equipment, ore

SF Flotation machine Flotation cell is widely used for separating non-ferrous metal, black metal, noble metal, non-metal mineral, raw body and materials of chemical industry,

SF Flotation Machine

Every cell has air inhaled, pulp sucked and flotation three functions; a closed flotation circuit and no need any auxiliary machine. Horizontal placing is good for the change of the flow sheet and reasonable cycling

Industrial Plant Flotation Machines in Banks

PROBLEM 1 How many No 15 (24×24) Denver “Sub-A” Cells are required to treat 50 tons of gold or load ore per day, with treatment time 12 minutes, dilution 3 to 1; and SG. 3.0 ? Tons (14 hours) x Treatment time

SF Flotation Machine-Fote Machinery-Fote Machiner

SF Flotation machine is mainly used for the selecting of non-ferrous metals like gold, copper, zinc, etc. 0-150mm Max Feeding Size. contact us inquire@sinoftm. A super-large-scaled modern green industrial

Silver Flotation Process,Silver Froth Flotation,Silver Ore

Associated with a small amount of copper, lead, zinc, sulfur and other sulfides and oxides, metal minerals account for 1.16%, the main gangue mineral is quartz and accounts for

Silver Ore Flotation Process, Equipment Mineral

Flotation separation is suitable for silver ore with fine inlaid particle siz e and strict symbiosis with sulfide ore. Gravity separation method is used to treat the silver ore separated from the monomer, that is, the silver with

SF Flotation Machine-Mining Processing Machine-Henan Daiwo

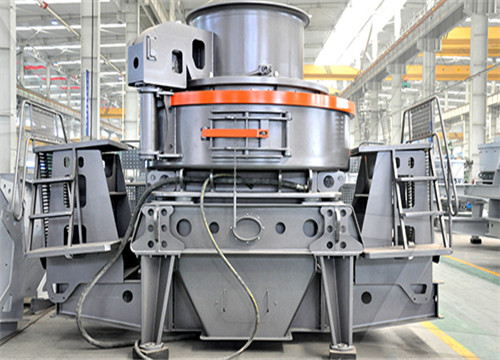

SF Flotation Machine. SF Flotation Machine is the representative equipment in the flotation production, mainly used in the flotation of nonferrous metals and rare metals, such as copper, gold, silver, zinc, lead, nickel, etc; and nonmetal materials, such as kaolinite, phosphorus, sulfur, etc.. Working Principle Of SF Flotation Machine: It uses in

SF Flotation machine Yantai Jinpeng Mining equipment, ore

Structure. SF Flotation machine. 1. belt wheel 2. aspirating tube 3. center cylinder 4. principal axis 5. cell body 6. cover board 7. Impeller 8. honeycomb duct 9. false bottom 10.

SF Flotation Cell, Flotation Equipment, Flotation Machine Xinhai

SF flotation cell is a mechanical agitation type flotation equipment with self-slurry suction and self-air suction Effective Volume 0.37~20m 3 Product Improvement Both sides of the impeller with back rake blades ensures double circulating of slurry inside the flotation tank. Forward type tank, small dead end, fast foam movement. CONSULT

Industrial Plant Flotation Machines in Banks

Description. The “pulp” (i.e. mineral-water slurry after grinding) is commonly passed through a hydrocylone to concentrate the “sands” and reject the “slimes” (the finest size fractions, say 30um), the slimes are

Silver Gold Recovery Flotation Process Mineral

2016年10月17日Flotation is then carried out, as shown below, in three rows of ten-cell “Sub-A” Machines, size No. 24, which comprise the roughing circuit. In the first cell of each machine, sometimes in the first

SF Flotation Machine

SF Flotation Machine. SF flotation machine is used for the separation of the nonferrous metals, black metals, precious metals, non-metal ore and industrial chemicals as well as other useful ore. It has the following

Froth Flotation Method JXSC Machine

2018年12月20日(2) When the flotation machine is used to treat polymetallic gold and silver ores, concentrates containing gold, silver and non-ferrous heavy metals can be effectively separated, which is

Silver Flotation Process,Silver Froth Flotation,Silver Ore Flotation

Associated with a small amount of copper, lead, zinc, sulfur and other sulfides and oxides, metal minerals account for 1.16%, the main gangue mineral is quartz and accounts for 98.84%.Dissemination size of silver is quite fine, generally between 0.074 and 0.005mm.To obtain a better silver flotation index, the combined process of flotation and

Assessment of two automated image processing methods to

2020年12月1日Bubble size measurements were conducted in the collection zone of industrial mechanical flotation cells (self-aerated and forced-air of 10–300 m 3) and columns (20–182 m 3). One hundred and six experimental conditions were studied. The McGill bubble size analyser (MBSA) was used for bubble sampling and image acquisition.

Flotation Machine an overview ScienceDirect Topics

Industrial flotation machines can be divided into four classes: (1) mechanical, (2) pneumatic, (3) froth separation, and (4) column. The mechanical machine is clearly the most common type of flotation machine in industrial use today, followed by the rapid growth of the column machine.

mill/sbm mining machines sf air flotation with forward type

Contribute to crush2022/mill development by creating an account on GitHub.

What Is A SF-Type Mechanical Stirring Flotation Machine?

2022年11月21日1. SF-type mechanical agitation flotation machine is a self-suction and self-suction mining flotation machine, which can be widely used in the separation of non-ferrous metals, ferrous metals, and

sbm/sbm sf mine ore selecting machines flotation machine.md

Contribute to dihog/sbm development by creating an account on GitHub.

Mining energy.gov.au

Advanced sensing technologies enable mining developers to visualise and quantify specific ore targets, resulting in much better return on effort and energy. Fluidised bed flotation cell. Historically, mineral ores have been crushed and ground down to a size small enough to undergo froth flotation to separate out the valuable minerals.

What Is A SF-Type Mechanical Stirring Flotation Machine?

2022年11月21日1. SF-type mechanical agitation flotation machine is a self-suction and self-suction mining flotation machine, which can be widely used in the separation of non-ferrous metals, ferrous metals, and

Flotation MachinesFlotation Cells 911Metallurgist

Flotation. The selection of flotation cell size and configuration can have a substantial influence upon installed cost and can contribute to operational efficiency. Two possible flotation configurations for a 500 metric ton per

SF Flotation Machine-Mining Processing Machine-Henan Daiwo

SF Flotation Machine. SF Flotation Machine is the representative equipment in the flotation production, mainly used in the flotation of nonferrous metals and rare metals, such as copper, gold, silver, zinc, lead, nickel, etc; and nonmetal materials, such as kaolinite, phosphorus, sulfur, etc.. Working Principle Of SF Flotation Machine: It uses in

SF Flotation machine Yantai Jinpeng Mining equipment, ore

Structure. SF Flotation machine. 1. belt wheel 2. aspirating tube 3. center cylinder 4. principal axis 5. cell body 6. cover board 7. Impeller 8. honeycomb duct 9. false bottom 10.

SF Flotation Cell, Flotation Equipment, Flotation Machine Xinhai

SF flotation cell is a mechanical agitation type flotation equipment with self-slurry suction and self-air suction Effective Volume 0.37~20m 3 Product Improvement Both sides of the impeller with back rake blades ensures double circulating of slurry inside the flotation tank. Forward type tank, small dead end, fast foam movement. CONSULT

SF Flotation Machine

SF Flotation Machine. SF flotation machine is used for the separation of the nonferrous metals, black metals, precious metals, non-metal ore and industrial chemicals as well as other useful ore. It has the following

Industrial Plant Flotation Machines in Banks

Description. The “pulp” (i.e. mineral-water slurry after grinding) is commonly passed through a hydrocylone to concentrate the “sands” and reject the “slimes” (the finest size fractions, say 30um), the slimes are

Silver Flotation Process,Silver Froth Flotation,Silver Ore Flotation

Associated with a small amount of copper, lead, zinc, sulfur and other sulfides and oxides, metal minerals account for 1.16%, the main gangue mineral is quartz and accounts for 98.84%.Dissemination size of silver is quite fine, generally between 0.074 and 0.005mm.To obtain a better silver flotation index, the combined process of flotation and

mill/sbm mining machines sf air flotation with forward type

Contribute to crush2022/mill development by creating an account on GitHub.

SF Flotation Machine_Jiangxi Tongli Mining Machinery

Product: SF Flotation Machine Type: SF series 1,Overview SF series of flotation machine is not only applied to separating the non-ferrous metal, ferrous metals, precious metals, and chemical raw materials, recycling

sbm/sbm sf mine ore selecting machines flotation machine.md

Contribute to dihog/sbm development by creating an account on GitHub.

Industrial Mixing Tank Mineral Flotation JXSC Machine

5. The Mine Mixing Drum has advanced performance, stable quality, even mixing and rapid discharging. JXSC supply tailor-made stainless steel mixing tank with an agitator, adopt advanced mixing technology, mineral mixer tank with factory price, combined with flotation machine and other gold mining equipment to obtain efficiency. chemical tanks

Mining energy.gov.au

Advanced sensing technologies enable mining developers to visualise and quantify specific ore targets, resulting in much better return on effort and energy. Fluidised bed flotation cell. Historically, mineral ores have been crushed and ground down to a size small enough to undergo froth flotation to separate out the valuable minerals.

Sulfidizing Behavior of Complex Lead-Silver Ore: A Flotation Study

2021年4月20日In the laboratory, the total recovery of lead and silver was 65.16% and 87.81%, respectively. In industrial closed-circuit testing, flotation alone was used, which produced a total lead recovery yield of 67.71%, and a total silver recovery yield of 87.64%. A 300 g ground sample was added to an XFG single-trough flotation machine at a