Crusher Process Design And Equipment

Crushers an overview ScienceDirect Topics

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based

Crushing Equipment Superior Industries U.S.

In the middle part of the 2010’s, Superior launched an aggressive strategy to improve reliability and performance of the products serving the

New Crusher Models Enhance Process Design Flexibility

Sandvik’s latest crusher models include the CH860 cone, designed for high-capacity secondary crushing, and the CH865 cone for high-reduction tertiary and pebble applications; both feature higher crushing forces

Rock Crushing Equipment Rock Crushers Kemper

Each type of crusher brings unique strengths and benefits to the process. Kemper Equipment specializes in designing the best crusher systems

Types of Rock Crushers Quarry Crushing Equipment

Here at Kemper Equipment, we offer the best performing crushing equipment that will work hard to make any finished products you plan to produce—including sand, gravel, fertilizer, specialty mineral products,

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

Crushers • Squeeze or press the material until it breaks • Mostly used to break large pieces of solid materials into small lumps • Use of crushers in agricultural operations is limited .

Crusher Process Equipment And Systems, Llc

Process Equipment and Systems, LLC. Application Matched Equipment Solutions. Crushing Plants, Crushers, Crusher Parts, Screeners, Misc Equipment.

Crushers For The Cement Industry MPD MPD-Inc

2022年10月31日The Dual Rotor Crusher from MachineProcess Design is made with heavy duty plate steel, robust rotors, and hard-faced crusher teeth, making it well suited

16" x 18" MachineProcess Design Single Rotor Crusher

Share/Save. Details. Specifications. TermsConditions. Request Similar. Used Machine and Process Design rotor crusher, stainless steel product contact surfaces, 16" x 18"

Crushers an overview ScienceDirect Topics

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact.

Cone Crusher an overview ScienceDirect Topics

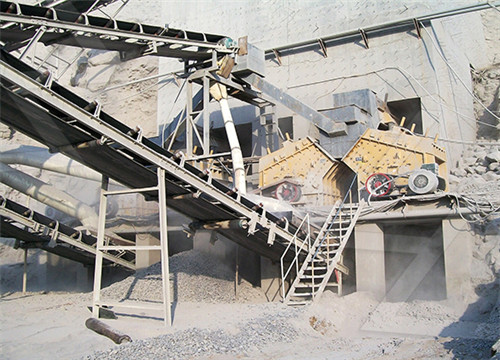

In this process, mined quartz is crushed into pieces using crushing/smashing equipment. Generally, the quartz smashing plant comprises a jaw smasher, a cone crusher, an impact smasher, a vibrating feeder, a vibrating screen, and a belt conveyor. The vibrating feeder feeds materials to the jaw crusher for essential crushing.

My Plant Planner Metso Outotec

Launch My Plant Planner. Design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance. My Plant Planner is packed full of unique

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

Crushers • Squeeze or press the material until it breaks • Mostly used to break large pieces of solid materials into small lumps • Use of crushers in agricultural operations is limited . Types Jaw crushers Gyratory crushers . Jaw crusher • Feed is admitted between two jaws, which are open at the top like V

MetallurgistMineral Processing Engineer

Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophy. The evaluation and prioritization of variables that affect the plant’s performance is the primary function. Laboratory Design: Layout and equipment list, process streamlining using samples

Crusher Process Equipment And Systems, Llc

Process Equipment and Systems, LLC. Application Matched Equipment Solutions. Crushing Plants, Crushers, Crusher Parts, Screeners, Misc Equipment.

Mineral Processing Design and Operations: An Introduction

Mineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processes. Application of theory to practice is explained at each stage, helping operators understand associated implications in each unit process. Covers the theory

How to choose mining crusher and screening machine?

2023年3月8日In summary, selecting the right mining crusher and screening machine is crucial for a successful operation. Consider the type of material being mined, production capacity, particle size

Machines Free Full-Text Developing and Testing of the Principle

In the current recycling process of reclaimed asphalt pavement (RAP), due to the serious damage of aggregate gradation and the large amount of aged asphalt still wrapped around the surface of the treated aggregate, the low recycling rate and poor performance of the recycled asphalt mixture are the major problems of RAP. In view of the shortcomings of

minimum equipment crusher plant design MiningQuarry

2013年4月27日The fundamental goal for the design of a crushing plant a good crushing plant: process design, equipment Crushing plants Domain Registered at Safenames TNT can design and supply complete crushing plants, incorporating all crushers, screens, structures, conveyors, bins, feeders, stockpiles and associated

16" x 18" MachineProcess Design Single Rotor Crusher

Used Machine and Process Design rotor crusher, stainless steel product contact surfaces, 16" x 18" feed opening, single rotor, on base with 15 hp, 230/460 volt xp motor, serial# 11480.

Minh Thanh Field Services Engineer ThyssenKrupp Industrial

I am a strong candidate with more than 14 years of working experience as Senior Service Engineer at Thyssenkrupp Industrial Solutions Vietnam, Head Of Mechanical Maintenance Section at Saint Gobain Vietnam Hai Phong Gyproc Plant, Head Of Quarry Equipment MaintenanceRepairing Section, Mechanical Engineer at Chinfon Cement Corporation.

2023 RUBBLE MASTER RM90GO! For Sale in

2023 RUBBLE MASTER RM90GO! For Sale in at centuryequipment. RUBBLE MASTER — RM 90GO! MOBILE CRUSHERInnovation in every detail — goes without saying in the world of the market leader for mobile crushers. The innovative refeeding system, the compact design for straightforward transport and the smart GO! system are

Manager / Sr. Manager Stone Crusher Design (14-20)

Calculations for the design of load-bearing steel structureshydraulics system design of Stone Crusher Equipment (Jaw, ConeScreening equipment). Preparation of 3D models and release of drawing for manufacturing in “Solid Edge” software. Design of weld structureshydraulic system integration. Design of Equipment layout.

Cone Crusher an overview ScienceDirect Topics

In this process, mined quartz is crushed into pieces using crushing/smashing equipment. Generally, the quartz smashing plant comprises a jaw smasher, a cone crusher, an impact smasher, a vibrating feeder, a vibrating screen, and a belt conveyor. The vibrating feeder feeds materials to the jaw crusher for essential crushing.

Mineral Processing Design and Operations ScienceDirect

The design of equipment use for the purpose is indicated in some details. Derivation of mathematical models for crushers and grinding equipment are illustrated and explained using examples and calculations of selected problems under operating conditions. Basics of process controls for efficient and economic modes of separation are

My Plant Planner Metso Outotec

Launch My Plant Planner. Design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance. My Plant Planner is packed full of unique

Crushing 101 Different types of crushers for distinctive needs

2020年12月17日Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top

MetallurgistMineral Processing Engineer

Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophy. The evaluation and prioritization of variables that affect the plant’s performance is the primary function. Laboratory Design: Layout and equipment list, process streamlining using samples

Crusher Process Equipment And Systems, Llc

Process Equipment and Systems, LLC. Application Matched Equipment Solutions. Crushing Plants, Crushers, Crusher Parts, Screeners, Misc Equipment.

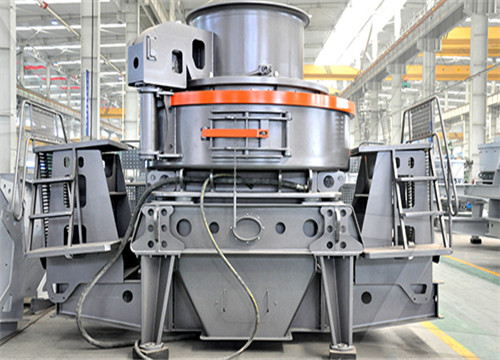

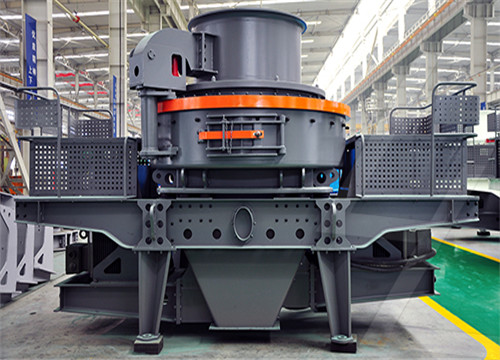

Crushing and screening equipment,ore beneficiation process design

2020年9月17日Jaw crusher, commonly known as "Laohukou", is one of the crushers with a long history and is still the most effective equipment for crushing hard materials. 2.Cone crusher The cone crusher uses the conical surface of the swing motion to periodically approach the fixed cone surface, so that the product material clamped

Mineral Processing Design and Operations: An Introduction

Mineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processes. Application of theory to practice is explained at each stage, helping operators understand associated implications in each unit process. Covers the theory

minimum equipment crusher plant design MiningQuarry

2013年4月27日The fundamental goal for the design of a crushing plant a good crushing plant: process design, equipment Crushing plants Domain Registered at Safenames TNT can design and supply complete crushing plants, incorporating all crushers, screens, structures, conveyors, bins, feeders, stockpiles and associated

Machines Free Full-Text Developing and Testing of the Principle

In the current recycling process of reclaimed asphalt pavement (RAP), due to the serious damage of aggregate gradation and the large amount of aged asphalt still wrapped around the surface of the treated aggregate, the low recycling rate and poor performance of the recycled asphalt mixture are the major problems of RAP. In view of the shortcomings of

How to choose mining crusher and screening machine?

2023年3月8日In summary, selecting the right mining crusher and screening machine is crucial for a successful operation. Consider the type of material being mined, production capacity, particle size

Minh Thanh Field Services Engineer ThyssenKrupp Industrial

I am a strong candidate with more than 14 years of working experience as Senior Service Engineer at Thyssenkrupp Industrial Solutions Vietnam, Head Of Mechanical Maintenance Section at Saint Gobain Vietnam Hai Phong Gyproc Plant, Head Of Quarry Equipment MaintenanceRepairing Section, Mechanical Engineer at Chinfon Cement Corporation.

16" x 18" MachineProcess Design Single Rotor Crusher

Used Machine and Process Design rotor crusher, stainless steel product contact surfaces, 16" x 18" feed opening, single rotor, on base with 15 hp, 230/460 volt xp motor, serial# 11480.

Custom Size Reduction SystemsEquipment Stedman Machine

Custom Size Reduction Systems. Stedman has the engineering experience to design, manufacture, and install custom crushing and bulk material conveyor handling systems. Bulk material conveyors are useful in handling and transporting a variety of materials throughout processing. Designing and deploying size-reduction systems takes experience.