Silica Sand Washing Plant Finland

Silica Sands Wash PlantEquipment Glass Sands Wash Plant

Proven Silica Sand Solutions. Our proven silica sand washing solutions produce a range of in spec materials including: Glass sand: 150-650 microns. Ultrafine sand / silica :

Sand Battery Trials Begin In Finland CleanTechnica

2022年7月5日The sand battery is the idea of two Finnish engineers, Markku Ylönen and Tommi Eronen. It is simplicity itself. Make a really big pile of sand. Heat it with excess

Silica sand washing plant equipment manufacturer

Silica sand processingSand washing plant EPC Sinonine silica sand processingsand washing plant specializes in producing sand products suitable for various industries, such as quartz sand, foundry sand, slab

Climate change: 'Sand battery' could solve green

2022年7月5日A storage device made from sand may overcome the biggest issue in the transition to renewable energy. But in a corner of a small power plant in western Finland stands a new piece of technology

Silica Sand ProcessingSand Washing Plant Equipment

2016年5月9日Silica sand low in iron is much in demand for glass, ceramic and pottery use, and for many of these applications clean, white sand is desired. Impurities such as clay slime, iron stain, and heavy

4 Operations Of Silica Sand Washing Plant Mining-pedia

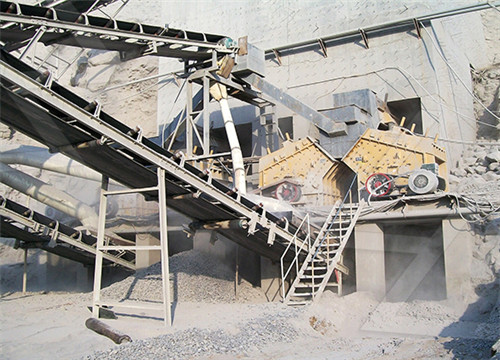

2020年11月2日In large-scale silica sand washing plant, it is better to use two-stage crushing, and impact crusher is better than jaw crusher. Then use a wet rod mill to grind the crushed silica sand to the particle size of

Silica sand washing plant process flow and equipment cost

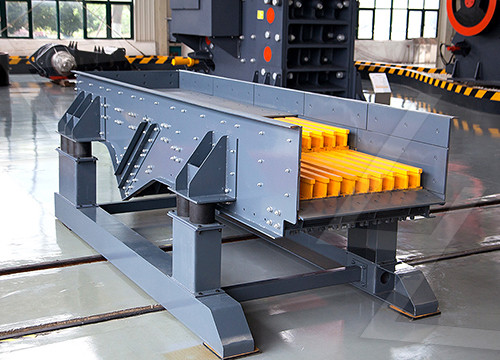

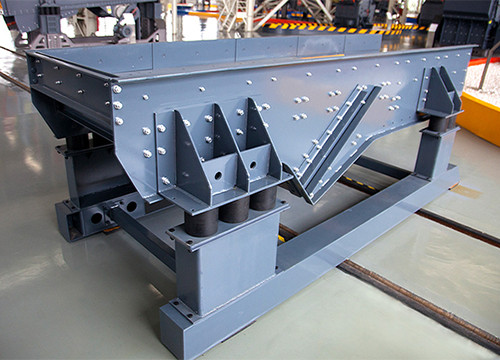

The silica sand washing plant mainly includes screening, cleaning, dehydration, fine material recovery, solid-liquid separation, sludge dewatering, and other aspects. The material is effectively screened,

METOFABRIK GLASS GRADE SILICA SAND WASHING

2018年5月28日Glass grade sand washing plant designed, manufactured and supplied by Metofabrik for Asahi Glass India Ltd, Roorkee, Uttarakhand, India.

Frac Sand Production Equipment Superior Industries

Then, in about 2010, demand dramatically increased as oil and gas producers discovered the durable, crush-resistant material. Overnight, frac sand production became the new gold rush! Headquartered in Western

Sand Battery Trials Begin In Finland CleanTechnica

2022年7月5日The sand battery is the idea of two Finnish engineers, Markku Ylönen and Tommi Eronen. It is simplicity itself. Make a really big pile of sand. Heat it with excess renewable electricity to around

Silica Sands Wash PlantEquipment Glass Sands Wash Plant

Our proven silica sand washing solutions produce a range of in spec materials including: Glass sand: 150-650 microns Ultrafine sand / silica : 30-150 microns Construction: -650 microns Coarse sand: 650 microns-3mm Oversize: +3mm LET'S TALK Latest from CDE Event Las Vegas, Nevada Mar 12 15 NSSGA Annual Convention 2023 Event

M2500 Employed on Silica Sand Washing Plant for Tooperang Quarry

The rejects from the spirals a sand product containing the liberated heavy mineral and iron oxide is delivered to the EvoWash sand washing plant sump and is destined for the concrete sand product. The silica sand slurry is delivered to the sand sump on the M2500 where it is then pumped to the integrated counter flow classification unit

Silica sand washing plant for Tooperang Quarry

At this point the silica sand is screened at 0.43 mm and the 0.43-7 mm material is sent to a separate EvoWash sand washing plant to allow for the production of concrete sand. Meanwhile, the 0-0.43 mm material is sent to an EvoWash fines recovery plant where following delivery to the EvoWash sump the material is then pumped to the integrated

4 Operations Of Silica Sand Washing Plant Mining

2020年11月2日This article will introduce these four operations one by one to help you better understand the entire process flow of the silica sand washing plant. 1. Pre-processing operations: The raw silica sand from

Silica Sand Processing Silica Sand Washing Plant

Silica sand must be clean to meet the users' specifications. LZZG sand washing machine does a good job here, the machine combin washing and fines recovery in one unit which greatly improve silica sand washing

Silica sand processing and sand washing plant EPC

This silica sand washing plant project is a high purity quartz sand production line with capacity 20tph. 30tph silica sand washing plant Oct The sand washing plant adopts pre-washing and cleaning, crushing

Production of useful Silica Sand from Lignite overburden

2023年3月7日The Neyveli silica sand washing plant is the second silica sand processing plant supplied by CDE Asia to the World leader in Glass manufacturing. It is also features dual pass washing process with water recovery and recycling system.

Frac Sand Production Equipment Superior Industries

Then, in about 2010, demand dramatically increased as oil and gas producers discovered the durable, crush-resistant material. Overnight, frac sand production became the new gold rush! Headquartered in Western

Silica SandSand Washing Plant by Sri K. Kaveri Ammal

Sri K. Kaveri Ammal Construction Silica Sand, Sand Washing PlantOffice Support Services from Cuddalore Tamil Nadu, India. IndiaMART. Get Best Price. X. Sri K. Kaveri Ammal Construction. Palayam, Cuddalore, Tamil Nadu GST 33AAZFS9853Q1ZS Verified Supplier. View Mobile Number. Home; ProductsServices.

VRX Silica fields cost estimate for processing plant at silica sand

2019年3月27日The processing plant is designed to wash, screen and attrition sand as well as remove heavy minerals to create a final product for delivery to customers. Project timelines.

Solutions LDHB

Our solutions cover sand washing plants, piling mud purification, River dredging, waste incinerator slag treatment. Home; Products. Sand Washing Machines; Sand Recycling Machines; Screening; Sludge Treatment; Silica Sand Washing Plant Flowchart. Quartz silica sand is a hard, wear-resistant, and chemically stable silicate mineral.

Silica / Sand Washing Plants (Starke Minerals) YouTube

We are manufacturing Single-Dual Sand/Silica Washing plant With High Rate Thickener (Water Management System) from 30 Ton Per Hour to 200 Ton Per Hour of production capacity based on...

Cost estimates revealed for sand processing plant Quarry

2019年4月12日VRX personnel have reported that the plant design for the production of a high purity silica sand product is suitable for the glass-making industry. CDE Global estimates that the cost of constructing the modular two million tonne per annum processing plant will be about $18.2 million.

Silica Sands Wash PlantEquipment Glass Sands Wash Plant

Our proven silica sand washing solutions produce a range of in spec materials including: Glass sand: 150-650 microns. Ultrafine sand / silica : 30-150 microns. Construction: -650 microns. Coarse sand: 650 microns-3mm. Oversize: +3mm.

M2500 Employed on Silica Sand Washing Plant for Tooperang Quarry

The rejects from the spirals a sand product containing the liberated heavy mineral and iron oxide is delivered to the EvoWash sand washing plant sump and is destined for the concrete sand product. The silica sand slurry is delivered to the sand sump on the M2500 where it is then pumped to the integrated counter flow classification unit

Silica sand washing plant for Tooperang Quarry

At this point the silica sand is screened at 0.43 mm and the 0.43-7 mm material is sent to a separate EvoWash sand washing plant to allow for the production of concrete sand. Meanwhile, the 0-0.43 mm material is sent to an EvoWash fines recovery plant where following delivery to the EvoWash sump the material is then pumped to the integrated

4 Operations Of Silica Sand Washing Plant Mining

2020年11月2日This article will introduce these four operations one by one to help you better understand the entire process flow of the silica sand washing plant. 1. Pre-processing operations: The raw silica sand from

Silica Sand ProcessingWashing Plant Equipment JXSC

2021年11月16日Quartz Silica Sand Process Plant. Material: Quartz Silica Sand Ore. Raw Condition: Raw ore is 4-200 mesh. The iron content of the ore is 200ppm, SiO2:99.58%. Capacity: 100TPH. Requirements for Finished Sand Products: particle size 50-200 mesh, SiO2 content: >99.8%, iron content≦lOOppm. Tail Waste Discharge

Silica Sand Processing Silica Sand Washing Plant

Silica sand must be clean to meet the users' specifications. LZZG sand washing machine does a good job here, the machine combin washing and fines recovery in one unit which greatly improve silica sand washing

SOMEVAM Invests in Second CDE Silica Sand Wash Plant

The state-of-the-art silica sand wash plant has the capacity to treat up to 200tph of sand, producing 100tph of silica glass sand for the glass industry, as well as a range of secondary products including fine silica sand for silica production, foundry sand, concrete sand and

Frac Sand Production Equipment Superior Industries

Silica sand was historically used and consistently produced for golf courses, glassmakers and some industrial consumers. Then, in about 2010, demand dramatically increased as oil and gas producers discovered the

VRX Silica fields cost estimate for processing plant at silica sand

2019年3月27日VRX Silica fields cost estimate for processing plant at silica sand projects The plant is designed for optimum utilisation at $18 million, with the total capital expenditure including plant feeder and water supply estimated at $25 million. A bankable feasibility study for Arrowsmith and Muchea projects is expected in September

GTBL silica sand washing ,screening ,iron removing plant

Weifang Guote Mining Equipment Co., Ltd, is Quartz/Silica Sand Process Equipment ManufacturerMain equipment :quartz slab sand making machine ,glass sand pro...

Solutions LDHB

Our solutions cover sand washing plants, piling mud purification, River dredging, waste incinerator slag treatment. Home; Products. Sand Washing Machines; Sand Recycling Machines; Screening; Sludge Treatment; Silica Sand Washing Plant Flowchart. Quartz silica sand is a hard, wear-resistant, and chemically stable silicate mineral.

Frac Sand McLanahan

Frac Sand Plants include a combination of McLanahan’s field-proven, state-of-the-art equipment that ensure silica deposits are processed to meet the strict demands of the industry. Based on the characteristics of the deposit as determined by McLanahan’s accredited lab, McLanahan will design a custom Frac Sand Plant to liberate silica

How to purify quartz sand?-Sinonine

2021年4月17日Quartz sand, also known as silica sand, is a common non-metallic mineral raw material. After beneficiation and purification, it can be made into high-purity quartz sand, which is widely used in glass, ceramics, metallurgy, casting and refractory industries. So, how to purify quartz sand?

Cost estimates revealed for sand processing plant Quarry

2019年4月12日VRX personnel have reported that the plant design for the production of a high purity silica sand product is suitable for the glass-making industry. CDE Global estimates that the cost of constructing the modular two million tonne per annum processing plant will be about $18.2 million.