Af Series Hydraulic Cone Crusher Mineral Material Crusher

A review of modeling and control strategies for cone

2021年8月15日The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a

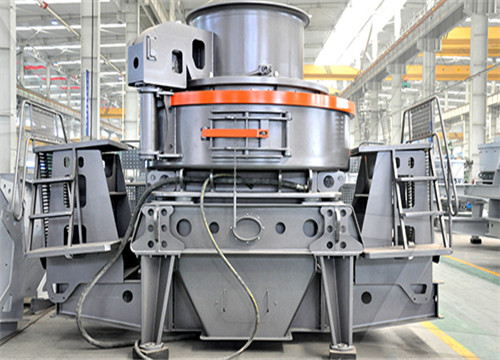

Vertical Shaft Impact Crusher AF Minerals Equipment

根据热度为您推荐•反馈

AF Series Hydraulic Cone Crusher Luoyang Dahua

AF series cone crusher is a kind of high-efficient fine cone crusher that manufactured by our company through adopting advanced technology from abroad. It applied the advanced laminated crushing technique at present

AF Series Hydraulic Cone Crusher Luoyang Dahua

AF Series Hydraulic Cone Crusher. Model: AF36、AF45、AF60. Throughput: AF36 (125-150mm),AF45 (215-265mm), AF60 (475-555mm) fine grain without influence of material properties. So AF cone

The pros and cons of cone crusher applications Quarry

2021年4月16日The mechanical factors that affect the production rate and quality of the material processed by a cone crusher include: Cone head diameter. Crushing chamber

Cone Crusher Luoyang Dahua

Materials Processing; Aggregates Production Process; Service; News. Company News; Industry News; Product Knowledge; Contact; 0086-379-/77/78 [email

Cone Crusher, SMH Cone Crusher, Hydraulic Cone Crusher

SMH series hydraulic cone crusher is a high-performance cone crusher. By optimized combination of the rotation rate, stroke and the crushing cavity, it realizes the laminated

Cone Crusher JXSC Mineral

Cone Crusher Structure The main parts of a cone crusher are Rack, horizontal axis, moving cone, balance wheel, eccentric sleeve, upper broken wall (fixed cone), lower

Hydraulic cone crusher HPT series DirectIndustry

Find out all of the information about the mpl IndustryTechnology Group Co., Ltd. product: hydraulic cone crusher HPT series. Contact a supplier or the parent company directly to get a quote or to find out a

Cone Crushers McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Applications Aggregates Coal Concrete Crushing Frac Sand Mining Jump To: How Cone Crushers Work Resources Why McLanahan FAQs FeaturesBenefits

Industrial Solutions Kubria cone crushers ThyssenKrupp

and the desired product size, thyssenkrupp cone crushers are tailored to your specific requirements. Crushers belonging to a specific series all feature identical bottom shells with a bear ing, hydraulic system, drive and auxiliary components. Kubria® cone crushers are available with mantle diameters ranging from 750 mm to 2,100 mm.

Mineral material crusher, Mineral material crushing plant All

cone crusher MCC-200 mobile for mineral material Capacity: 200 t/h 250 t/h Tons Per Hour Crusher Type: Cone Crusher -Maximum Feeding Size: 250mm -Vibrating Screen Size and Deck: 1600x4500mm 3-4 decks -Total Motor Power: 200 kW MCC-200 is a combination of: • Bunker (Hopper) • jaw crushing and screening plant MCK-65

The pros and cons of cone crusher applications Quarry

2021年4月16日The mechanical factors that affect the production rate and quality of the material processed by a cone crusher include: Cone head diameter. Crushing chamber slope (angle). Cone head stroke. Gyrating speed. Manganese liner profile. Closed side setting (CSS). Crushing force, monitored as operating pressure. Applied power.

11.19.2 Crushed Stone Processing and Pulverized Mineral

Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 2.5 to 10 centimeters (1 to 4 inches). The material (throughs) from the second level of the screen bypasses the secondary crusher because it is sufficiently small for the last crushing step.

Cone Crusher Explained saVRee

Purpose of Crushers. A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste (gangue) material.

Cone Crusher, SMH Cone Crusher, Hydraulic Cone Crusher

SMH series hydraulic cone crusher is a high-performance cone crusher. By optimized combination of the rotation rate, stroke and the crushing cavity, it realizes the laminated crushing and improves the yield greatly. Capacity 30-1566t/h Max feeding size 35mm-450mm Raw materials

HPT Multi-cylinder Hydraulic Cone Crusher

When the HPT Hydraulic Cone Crusher is working, the motor drives the transmission shaft rolling through the pulley and the V-belt. The transmission shaft drives the eccentric bush rolling around the main shaft through the large and small bevel gears.The eccentric bush drives the moving cone to do the swing motion, to make the moving cone sometimes

Hydraulic cone crusher HST series DirectIndustry

Find out all of the information about the mpl IndustryTechnology Group Co., Ltd. product: hydraulic cone crusher HST series. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale. stationary for mineral material. impact crusher CI5X2023. stationary primary sand

Cone Crusher Crushing Equipment Products Luoyang Dahua

It can be used for crushing hard materials, uses laminating crushing principle, large offset, automatic iron protection function, the crushed particle are in good shape. menu. Home; About Us. HPY Multi-cylinder Hydraulic Cone Crusher. AF Series Hydraulic Cone Crusher. Customer Cases. 250t/h construction sand aggregates production line in

A review of modeling and control strategies for cone crushers in

2021年8月15日DOI: 10.1016/j.mineng.2021.107036 Corpus ID: ; A review of modeling and control strategies for cone crushers in the mineral processing and quarrying industries @article{Yamashita2021ARO, title={A review of modeling and control strategies for cone crushers in the mineral processing and quarrying industries}, author={Andre

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Hydraulic Cone Crusher_百度百科

Hydraulic cone crusher incorporates three crushing styles; its feeding style incorporates material on material, materials on iron and falling at sides. Customers can adjust the machines according to their own demand. This cone crusher realizes multiple functions in one machine, which is a big breakthrough in sand making field.

Material Crusher Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher, impact crusher, cone crusher, the largest production base in Shanghai, the famous crusher equipment manufacturers in China Shanghai Family owned and operated for over 30 years! Our materials can be used for mortar and plaster, concrete and bedding, drainage and

Industrial Solutions Kubria cone crushers ThyssenKrupp

and the desired product size, thyssenkrupp cone crushers are tailored to your specific requirements. Crushers belonging to a specific series all feature identical bottom shells with a bear ing, hydraulic system, drive and auxiliary components. Kubria® cone crushers are available with mantle diameters ranging from 750 mm to 2,100 mm.

Mineral material crusher, Mineral material crushing plant All

cone crusher MCC-200 mobile for mineral material Capacity: 200 t/h 250 t/h Tons Per Hour Crusher Type: Cone Crusher -Maximum Feeding Size: 250mm -Vibrating Screen Size and Deck: 1600x4500mm 3-4 decks -Total Motor Power: 200 kW MCC-200 is a combination of: • Bunker (Hopper) • jaw crushing and screening plant MCK-65

The pros and cons of cone crusher applications Quarry

2021年4月16日CONE CRUSHER TYPES Cone crushers can be categorised into three main design types. With floating bowl and screw bowl cone crushers the upper frame raises to open CSS or relieve crushing pressure. The third type the spider-bearing cone crushers incorporate a shaft supported by a hydraulic piston which controls CSS and

11.19.2 Crushed Stone Processing and Pulverized Mineral

Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used), which typically reduces material to about 2.5 to 10 centimeters (1 to 4 inches). The material (throughs) from the second level of the screen bypasses the secondary crusher because it is sufficiently small for the last crushing step.

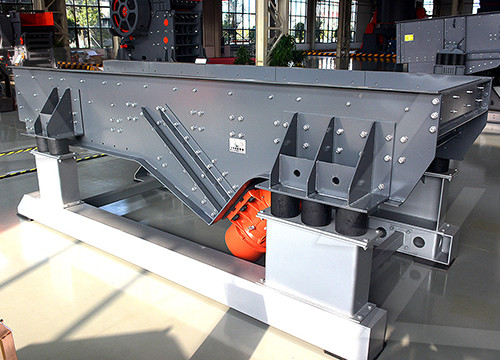

Yeco Machinery Leading Crushing Equipment Supplier in China

Our professional and aspiring team has made a number of milestones in designing machines for aggregate production and mineral material processing. What We Do As a leading manufacturer and supplier in China, we are committed to providing high performance jaw crushers,cone crushers,vibrating feeders,screens,belt conveyors,wear

Cone Crusher Explained saVRee

Purpose of Crushers. A crusher is a machine designed to reduce the size of large rocks to smaller rocks, gravel, sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste (gangue) material.

HPT Multi-cylinder Hydraulic Cone Crusher

When the HPT Hydraulic Cone Crusher is working, the motor drives the transmission shaft rolling through the pulley and the V-belt. The transmission shaft drives the eccentric bush rolling around the main shaft through the large and small bevel gears.The eccentric bush drives the moving cone to do the swing motion, to make the moving cone sometimes

Cone Crusher Crushing Equipment Products Luoyang Dahua

It can be used for crushing hard materials, uses laminating crushing principle, large offset, automatic iron protection function, the crushed particle are in good shape. menu. Home; About Us. HPY Multi-cylinder Hydraulic Cone Crusher. AF Series Hydraulic Cone Crusher. Customer Cases. 250t/h construction sand aggregates production line in

Hydraulic cone crusher HPT series DirectIndustry

Find out all of the information about the mpl IndustryTechnology Group Co., Ltd. product: hydraulic cone crusher HPT series. Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale. stationary for mineral material. impact crusher CI5X2023. stationary primary sand

A review of modeling and control strategies for cone crushers in

2021年8月15日Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation of rock materials. Control systems for cone crusher settings are widely used to compensate for wear and to Expand 6 Save Alert Cone Crusher Performance C. Evertsson Geology 2000 Cone crushers are used by both the aggregate producing and

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Hydraulic Cone Crusher_百度百科

Hydraulic cone crusher incorporates three crushing styles; its feeding style incorporates material on material, materials on iron and falling at sides. Customers can adjust the machines according to their own demand. This cone crusher realizes multiple functions in one machine, which is a big breakthrough in sand making field.

Material Crusher Crusher Mills, Cone Crusher, Jaw Crushers

Material crusher US Patent Description Patent Description: Material crushers are generally used to crush and reduce the size of material and are employed in a variety of fields, including but not limited UniformMaterialDischargeDirectlytotheCrusher FMC Technologies

HP Series Hydraulic Cone Crusher Yeco Machinery

HP Series Multi-cylinder hydraulic cone crusher which has the lowest consumption and greatest crushing power, is manufactured based on the technology of , which not only improves productivity and efficiency, but expands the scope of application. HP cone crusher has an unmatched level of crushing performance in general crushing, fine