Large Production Granite Stone Crushing Machine Granite Impact Crusher

6 Granite Crushers for Efficient Granite Crushing Fote

进一步探索

Rock Crusher MachinesPulverizers Williams CrusherHow much force is needed to break a cubic meter of stone?根据热度为您推荐•反馈

Granite Crusher Granite Stone Crushing Plant

2021年12月1日For the granite stone crushing plant with large output, the three-stage crushing machine should be used as far as possible, the jaw crusher + fine jaw

Granite Crusher High Efficiency And Good In Shapes

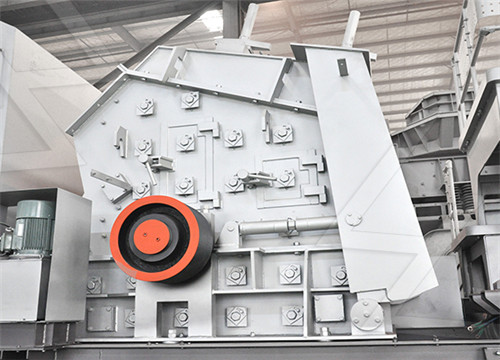

The impact granite crusher machine is suitable for crushing materials with low toughness and brittleness of medium hardness and below. These materials include marble, granite,

5 Granite Stone Crushers: Which is Best for Granite Crushing?

2023年1月4日Granite stone crushing machine can be divided into three categories according to the feed and product particle size: Coarse crusher: from 1500~500mm to

Granite Crushing Plant Granite Crusher For Sale Aggregate

When planning a granite crushing plant, the cost of investment and the cost of production matters the most. To be specific, the output demand, final size, and shape requirement

(PDF) Design of Impact stone crusher machine

2019年5月31日Rocks go through a series of crushing stages to produce the final aggregate size which suit customer’s needs. Aggregate crushers suffer from many problems in reality that affect its production

Hot Sale Granite Impact Crusher Shanghai of Stone Crushing Line

Quality Hot Sale Granite Impact Crusher Shanghai find quality Stone Crushing Line Machines, CrusherStone Crushing Line Machines from Shanghai Lipu Heavy

Granite Stone Cruching Machine Crusher Mills

Granite Stone Crushing Machine ManufacturersGranite Stone Crushing Machine Suppliers Directory Find a Granite Stone Crushing Machine Manufacturer and

20tph Mobile Type Limestone Gravel Granite Hammer

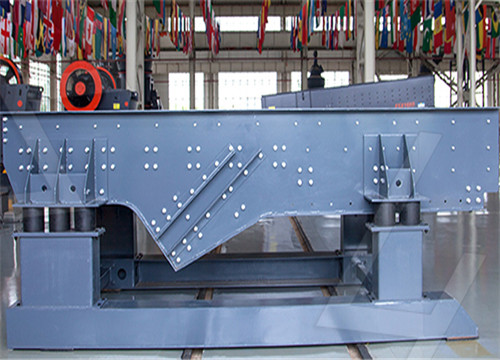

20tph Mobile Type Limestone Gravel Granite Hammer Crusher,Jaw Crusher With Vibrating Screen Line Plant,Find Complete Details about 20tph Mobile Type Limestone Gravel

Impact Crushers Parker Plant

The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications. No shear or

Granite Crushing Solution Eastman Rock Crusher

The large pieces of granite are evenly fed by the vibrating feeder through the silo, and conveyed to the jaw crusher for coarse crushing. The finished product is about 10 cm. It is transported to the cone crusher for medium

Granite Crushing Plant Granite Crusher For Sale Aggregate Crushing

When planning a granite crushing plant, the cost of investment and the cost of production matters the most. To be specific, the output demand, final size, and shape requirement decide the layout of a granite crushing plant. The configuration can be flexible according to different production demands.

Rock Crusher Eastman Rock Crusher

impact crusher Capacity: 10-350t/h Feed Size: 100-500mm Output Size: 10-80mm hammer crusher Capacity: 1-75t/h Feed Size: 0-400mm Output Size: 0-15mm HP cone crusher Capacity: 70-1200t/h Feed Size: 5

Granite Crushing Plant AIMIX Group

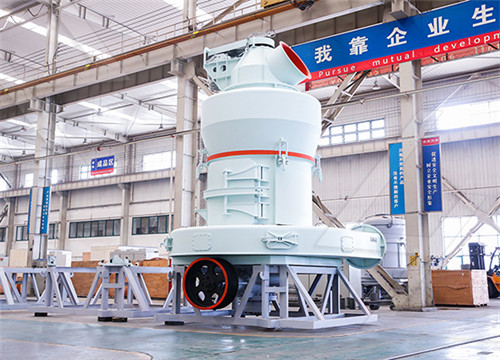

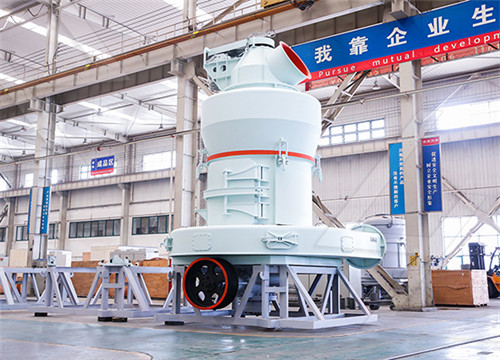

Granite crushing production line has advantages of high automation, high crushing rate, energy saving, large output, uniform particle size and good brain shape. It is suitable for highway, bridge and other large, medium

Hot Sale Granite Impact Crusher Shanghai of Stone Crushing

Quality Hot Sale Granite Impact Crusher Shanghai find quality Stone Crushing Line Machines, CrusherStone Crushing Line Machines from Shanghai Lipu Heavy Industry Co., Ltd. of China Suppliers .

Granite Stone Crusher amcrushers

Granite Jaw Crusher. Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10-100 mm. Jaw crusher has super wear resistance and impact resistance, very flexible adaptability, more safe and reliable operation process

How to build a granite crushing plant?

2022年12月29日A crushing machine, such as a jaw crusher, cone crusher, or impact crusher, to reduce the size of the granite rocks. Vibrating screens to separate the crushed granite into different...

Granite Crusher For Sale Track-Mounted Mobile Granite Crusher Machine

A professional mobile jaw crusher and a mobile cone crusher can complete the production. Jaw crusher and cone crusher are commonly used for rocks and stones with high hardness such as granite. Put the granite evenly into the mobile jaw crusher for crushing, and transfer the produced materials to the mobile cone crusher.

Granite Stone Crushing Plant ZENITH Crusher

2022年3月10日The impact crusher processes various kinds of material with crushing compression strength not more than 350MPa, featuring firm structure, stable performance, large capacity, even producing granularity, convenient maintenance and economical running expense, and widely applied in the areas of mining, construction material, smelting,

20tph Mobile Type Limestone Gravel Granite Hammer Crusher,Jaw Crusher

20tph Mobile Type Limestone Gravel Granite Hammer Crusher,Jaw Crusher With Vibrating Screen Line Plant,Find Complete Details about 20tph Mobile Type Limestone Gravel Granite Hammer Crusher,Jaw Crusher With Vibrating Screen Line Plant,Mobile Crusher Equipment Supplier,Mobile Hammer Concrete Stone Crusher For Quarry Project,Rock

Process Design Of Granite Crushing Production Line

2022年8月24日As for the crusher machines used for granite crushing production line, they can be divided into the jaw crusher, impact crusher, and cone crusher. 1. Coarse crushing: The raw...

Types of Rock Crushers Quarry Crushing Equipment Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing.

Granite Stone Crusher in Nigeria-mpl Industrial Technology Group

2021年8月18日Granite Jaw Crusher. Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10-100 mm. Jaw crusher has super wear resistance and impact resistance, very flexible adaptability, more safe and reliable

Granite Rock Crusher Mobile JawImpact Crushers RUBBLE

Hard-Rock Impactor Crushing 10" Granite. The unique VORTEX impact crushing chamber surpasses other impactors in wear and reduction ratio making this machine ideal for processing granite. The RM V550GO! mobile impact crusher combines a jaw crusher, impact crusher, and screening plant to process hard granite efficiently.

Impact Crushers Parker Plant

The Kubitizer is the genuine Parker fixed hammer impact crusher for the production of high quality, high strength cubical shaped aggregates in secondary or tertiary, low abrasion applications. No shear or

Impact Crusher With Capacity Of 15-350 Tons Per Hour

Introduction of impact crusher This series product,abosorbing advantages of similar production abroad,optimized design,crush material whose compression strength not more than 320Mpa,such as lime stone,granite and basalt and etc.Enjoy the advantage of bigcushing ratio,high crushing efficiency,even cubic discharging,convenient maintenance.

Granite Crushing Plant Granite Crusher For Sale Aggregate Crushing

When planning a granite crushing plant, the cost of investment and the cost of production matters the most. To be specific, the output demand, final size, and shape requirement decide the layout of a granite crushing plant. The configuration can be flexible according to different production demands.

(PDF) Design of Impact stone crusher machine

2019年5月31日Rocks go through a series of crushing stages to produce the final aggregate size which suit customer’s needs. Aggregate crushers suffer from many problems in reality that affect its production

Granite Crushing Plant AIMIX Group

Granite crushing production line has advantages of high automation, high crushing rate, energy saving, large output, uniform particle size and good brain shape. It is suitable for highway, bridge and other large, medium

Granite Stone Crusher amcrushers

Granite Jaw Crusher. Jaw crusher is kind of granite crusher which performs as the primary crusher, the feeding size of which can reach 1000mm, and also the final size of granite dust may be adjusted from 10-100 mm. Jaw crusher has super wear resistance and impact resistance, very flexible adaptability, more safe and reliable operation process

Hot Sale Granite Impact Crusher Shanghai of Stone Crushing

Quality Hot Sale Granite Impact Crusher Shanghai find quality Stone Crushing Line Machines, CrusherStone Crushing Line Machines from Shanghai Lipu Heavy Industry Co., Ltd. of China Suppliers .

Granite Crusher For Sale Track-Mounted Mobile Granite Crusher Machine

Working Process Of The Granite Crushing Machine The raw material of the whole crushing production line is granite with a size less than or equal to 660mm. Since the hardness of granite is relatively high, it is important to choose the right type of crushers to crush or unnecessary wear will happen.

Granite Stone Crusher in Nigeria-mpl Industrial Technology Group

2021年8月18日As for the crusher machines used for granite crushing production line, they can be divided into the jaw crusher, impact crusher, and cone crusher. 1. Coarse crushing: The raw granite ore is continuously and uniformly fed to the jaw crusher by the vibrating feeder through the silo.

Granite Crusher Stone Crushing Plant Design and

1. Description of granite Granite is a good type of building stone with a uniform structure, hard texture and beautiful color. The density is 2790~3070kg/m3, the compressive strength is 1000~3000kg/cm2, the

Types of Rock Crushers Quarry Crushing Equipment Kemper

As the first stage in a crushing circuit following extraction from a mine site, (or in the case of recycled asphalt production, delivery to the RAP processing plant via truck transport), primary crushing reduces material to a size and shape that can be handled by the secondary crusher.

Impact crusher, HCP- Impact crusher, Granite crusher,Limestone crusher

CHP (A) / CHS (A) series impact crusher is a leading international granite, limestone, concrete, lime, gypsum, slaked lime crushing equipment is widely used for crushing various soft and hard ore primary crushing andtwo broken rough broken, broken, broken bits. YIFAN Machine is China's leading supplier of crusher production. It Supply

Stone Crusher ConeJaw Crushers Machine Manufacturer

PF-I series impact crusher can crush materials with length less than 100 ~ 500 mm and its compressive strength can reach up to 350 MPA, which has the advantages of large crushing ratio. It is suitable for crushing medium hard materials, such as limestone in cement plant. Mining rock crusher machine 1 Adjustable fine crusher