Main Shaft Position System For Crushing Equipment

Crushing Systems

crushing system capabilities equipment, whether it is our gyratory or cone Mantle Position Indicator Available TS Crusher Sizes (mm) 900 x 1400 1100 x

SANDVIK CS550 CONE CRUSHER

Main shaft position Calculated CSS (based on main shaft position) Lubrication oil temperature Liner wear Historical data log AUTOMATIC SETTING REGULATION

Cone Crushers McLanahan

Sleeve bearings make removal and installation of the MSP Cone Crusher head and main shaft simple. The tapered main shaft fits into a large opening at the upper end of the

TLC for Primary Crushers EMJ

“By optimizing the main shaft position, we create a more effective and constant wear profile, which allows the end user to get full wear out of liners.” is in the early

SANDVIK CS840i CONNECTED CONE CRUSHER

Oil tank reservoir capacity Supplies oil to the main lubrica-tion system, Pinion lubrication systems and to the Hydroset system. No. of doors 3 No. of inspection hatches 2 located

Cone Crushers Moore Watson Ltd

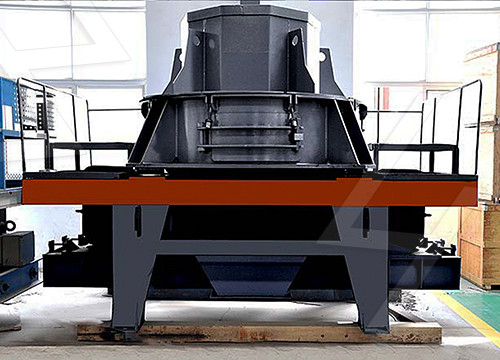

The MP Cone Crusher is an excellent choice as secondary or tertiary crushing equipment and the compact structure makes it easier for maintenance and also ideal for portable

Crusher Main Shaft Positioning Systems Crusher Mills, Cone

Hydraulically operated and controlled positioning system for quick and effective adjustment CG series of primary gyratory crushers liming Mining and A hydraulic cylinder

Damage “main shaft” CH660 cone crusher

2019年3月12日https://commercialpropertysalvage/2019/03/12/mining-aggregate-cone-crushing-main-shaft-equipment-for-sale/281-905

Main Shaft Position System For Crusher-Crusher

Main shaft position system for crushermain shaft position system for crusherMain shaft position system for crusher crusher wikipedia the free encyclopedia a crusher is a

SANDVIK CH830i CONNECTED CONE CRUSHER

2019年9月30日tertiary crushing, designed for crushing applications in mines or large sized quarries. Each crusher has a hydraulically supported main shaft which is supported at both ends. With a robust design, adjustable eccentric throw, a constant intake opening, high performance can be achieved by proper selection of a OEM crushing

Crushing Systems

crushing system capabilities equipment, whether it is our gyratory or cone Mantle Position Indicator Available TS Crusher Sizes (mm) 900 x 1400 1100 x 1800 1300 x 1800 1400 x 2100 1600 x 2400 1600 x 2900 Main Shaft 18. Eccentric 19. Counterweight 20. Gear 21. Countershaft 22. Pinion 23. Wedge

Industrial Solutions Gyratory crushers ThyssenKrupp

The crushing gap is adjusted by hydraulically lifting or lowering the main shaft. This hydraulic shaft adjustment is used mainly when crushing abrasive material and when the gap frequently needs to be corrected. It also serves as overload protection when uncrushable tramp material enters the crushing chamber. Moreover, the main shaft

SANDVIK CS550 CONE CRUSHER

Main shaft position Calculated CSS (based on main shaft position) Lubrication oil temperature Liner wear Historical data log AUTOMATIC SETTING REGULATION INTELLIGENT (ASR iTM) ASRi is the cone crusher’s setting and regulation system. REGULATION FUNCTIONS (CRUSHING PROGRAMS) Auto-CSS The ASRi aims to

TLC for Primary Crushers EMJ

“By optimizing the main shaft position, we create a more effective and constant wear profile, which allows the end user to get full wear out of liners.” is in the early stages of developing a comprehensive maintenance management system for its Excel-Raptor cone and gyratory crusher lines.

SANDVIK CS840i CONNECTED CONE CRUSHER

Oil tank reservoir capacity Supplies oil to the main lubrica-tion system, Pinion lubrication systems and to the Hydroset system. No. of doors 3 No. of inspection hatches 2 located on top of unit Cabinet material Metal Tank unit dimensions (LxWxH) 1,980x1,130x2,000 mm Dry weight 865 kg MAIN CRUSHER LUBRICATION SYSTEM

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

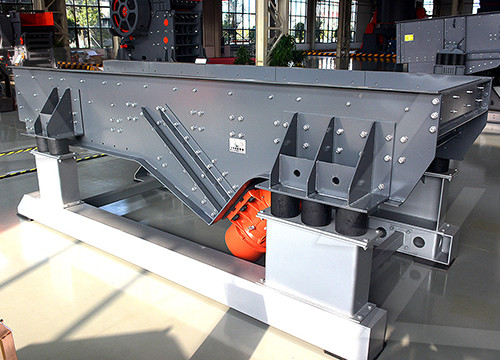

main shaft is supported at the Centre by means of ball bearings as the distance between the pulley and the crank is more. This bearings eases the power transmission and reduces the transmission losses [2]. These bearings also reduce the friction on the rotating shaft and also prevents bending or torsional stresses acting on the horizontal rod

Crusher Main Shaft Positioning Systems Crusher Mills, Cone Crusher

Gyratory crusher: Shannon: 9/22/1998: : Positioning device for concaves of cone crushers: this invention elates to the main shaft assembly and head nut system.

crusher/sbm main shaft assembly for a gyratory crusher.md at main

Contribute to yunan88/crusher development by creating an account on GitHub.

Damage “main shaft” CH660 cone crusher aggregate system

2019年3月12日https://commercialpropertysalvage/2019/03/12/mining-aggregate-cone-crushing-main-shaft-equipment-for-sale/281-905

Cone Crusher Parts Mineral ProcessingMetallurgy

2017年2月19日The mainshaft is of high grade forged steel, annealed for stress relief. It is tapered to gauge for head center fit. The bottom of the shaft is fitted with a polished bronze step bearing. The journal for the spider bearing is formed by a sleeve shrunk on the shaft on the 51, 60 and 84-in. crushers.

SANDVIK CH860CH865 CONE CRUSHER Mining

2019年3月13日Main shaft position Calculated CSS (based on main shaft position) Lubrication oil temperature Liner wear Historical data log AUTOMATIC SETTING REGULATION INTELLIGENT (ASRiTM) ASRi is the cone crusher’s setting and regulation system. REGULATION FUNCTIONS (CRUSHING PROGRAMS) Auto-load The ASRi

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501). The crushing head is carried on a short solid main shaft (515

Hydraulic control system for gyratory crusher provided with safety

The main shaft of a gyratory crusher is usually hydraulically supported by a piston such that the vertical position of the main shaft can be adjusted. The hydraulic circuit in such crushers is usually also provided with a safety system for overload situations.

Crushing Systems

crushing system capabilities equipment, whether it is our gyratory or cone Mantle Position Indicator Available TS Crusher Sizes (mm) 900 x 1400 1100 x 1800 1300 x 1800 1400 x 2100 1600 x 2400 1600 x 2900 Main Shaft 18. Eccentric 19. Counterweight 20. Gear 21. Countershaft 22. Pinion 23. Wedge

SANDVIK CH830i CONNECTED CONE CRUSHER

tertiary crushing, designed for crushing applications in mines or large sized quarries. Each crusher has a hydraulically supported main shaft which is supported at both ends. With a robust design, adjustable eccentric throw, a constant intake opening, high performance can be achieved by proper selection of a OEM crushing chamber.

SANDVIK CS840i CONNECTED CONE CRUSHER

Oil tank reservoir capacity Supplies oil to the main lubrica-tion system, Pinion lubrication systems and to the Hydroset system. No. of doors 3 No. of inspection hatches 2 located on top of unit Cabinet material Metal Tank unit dimensions (LxWxH) 1,980x1,130x2,000 mm Dry weight 865 kg MAIN CRUSHER LUBRICATION SYSTEM

Industrial Solutions Gyratory crushers ThyssenKrupp

The crushing gap is adjusted by hydraulically lifting or lowering the main shaft. This hydraulic shaft adjustment is used mainly when crushing abrasive material and when the gap frequently needs to be corrected. It also serves as overload protection when uncrushable tramp material enters the crushing chamber. Moreover, the main shaft

SANDVIK CS550 CONE CRUSHER

Main shaft position Calculated CSS (based on main shaft position) Lubrication oil temperature Liner wear Historical data log AUTOMATIC SETTING REGULATION INTELLIGENT (ASR iTM) ASRi is the cone crusher’s setting and regulation system. REGULATION FUNCTIONS (CRUSHING PROGRAMS) Auto-CSS The ASRi aims to

TLC for Primary Crushers EMJ

“By optimizing the main shaft position, we create a more effective and constant wear profile, which allows the end user to get full wear out of liners.” is in the early stages of developing a comprehensive maintenance management system for its Excel-Raptor cone and gyratory crusher lines.

SANDVIK CH840i CONNECTED CONE CRUSHER

tertiary crushing, designed for crushing applications in mines or large sized quarries. Each crusher has a hydraulically supported main shaft which is supported at both ends. With a robust design, adjustable eccentric throw, a constant intake opening, high performance can be achieved by proper selection of a OEM crushing chamber.

Crusher Main Shaft Positioning Systems Crusher Mills, Cone Crusher

Gyratory crusher: Shannon: 9/22/1998: : Positioning device for concaves of cone crushers: this invention elates to the main shaft assembly and head nut system.

Damage “main shaft” CH660 cone crusher aggregate system

2019年3月12日https://commercialpropertysalvage/2019/03/12/mining-aggregate-cone-crushing-main-shaft-equipment-for-sale/281-905

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

main shaft is supported at the Centre by means of ball bearings as the distance between the pulley and the crank is more. This bearings eases the power transmission and reduces the transmission losses [2]. These bearings also reduce the friction on the rotating shaft and also prevents bending or torsional stresses acting on the horizontal rod

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501). The crushing head is carried on a short solid main shaft (515

Hydraulic control system for gyratory crusher provided with safety

When a noncrushable particle enters the crusher, the system allows the piston and thereby the main shaft to move downwards and thus let the particle go through the crusher. Thereafter the main shaft must rise to the original position to continue the crushing process. In such known systems there is a pressure relief valve and a pressure

SANDVIK CH860CH865 CONE CRUSHER Mining

2019年3月13日Main shaft position Calculated CSS (based on main shaft position) Lubrication oil temperature Liner wear Historical data log AUTOMATIC SETTING REGULATION INTELLIGENT (ASRiTM) ASRi is the cone crusher’s setting and regulation system. REGULATION FUNCTIONS (CRUSHING PROGRAMS) Auto-load The ASRi

SANDVIK CH890iCH895i CONNECTED CONE CRUSHER

2019年3月13日CONE CRUSHER CH890i and CH895i are technologically advanced, high-capacity cone crushers designed for crushing applications in mines or large sized quarries. Each crusher has a hydraulically supported main shaft which is supported at both ends. The main shaft is now 65% stronger and both the top