Method Of Install Grinder Machine

High-precision grinding machine installation method

The method comprises the following steps: mounting an inertia block of the grinding machine; mounting the bed piece of the grinding machine; mounting the head stock;

Install angle grinder disc Angle grinder safety YouTube

2013年12月30日Install angle grinder disc Angle grinder safety Ultimate Handyman 498K subscribers Subscribe 630K views 9 years ago Angle grinders are a very versatile tool, but mounting the disc

Proper Mounting of a Grinding Wheel Norton Abrasives

2008年9月5日Proper steps in mounting a grinding wheel are as follows: Handle and store grinding wheels in a careful manner. Handle and store all grinding wheels as if they were made of glass! Select the proper

Grinding Machine: Types, Parts, WorkingOperations

2023年3月2日A tool and cutter grinder makes use of a CNC machine tool with up to 5 axes and multiple grinding wheels. These devices are used for sharpening and producing milling cutters such as drills, endmills, and

14 Types of Grinding Machines [Working, Diagram

2021年11月23日A grinder wheel is fitted each on both sides of the shaft of the electric motor. Tools rests are also provided with them. These are the most widely used in the workshops. Edges of all types of cutting tools are

Grinding Machine: Definition, Parts, Working Principle,

A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation

Machining 101: What is Grinding? Modern Machine Shop

2021年7月3日Evan Doran. Associate Editor. On its surface, grinding seems simple: a machine takes a rotating tool (usually a wheel) with abrasive grains and applies it to a workpiece’s surface to remove

Grinding Machine Installation How to do wiring of Three

2019年11月8日in this video we have shown installation procedure of 3 phase bench type grinding machine. 3 phase electrical wiring connection of bench type grinding machine. we have installed...

Reliability Modeling and Evaluation Method of CNC Grinding

The CNC (computer numerical control) grinding machine tool is widely used in automotive, aircraft, and other industries to grind precise parts as the last process, and its reliability

Bench Grinder Basics You Need to Know — The

2018年10月2日To avoid ruining the edge of a tool by overheating, keep water nearby to cool the tool. A good technique is to move the tool once across the bench grinder for no more than a few seconds. Then dip it in

Chapter 5: Surface Grinder Manufacturing Processes

• The first step in using the surface grinder, is to make sure that the material you wish to shape can be used in the grinder. Soft materials such as aluminum or brass will clop up the abrasive wheel and stop it from

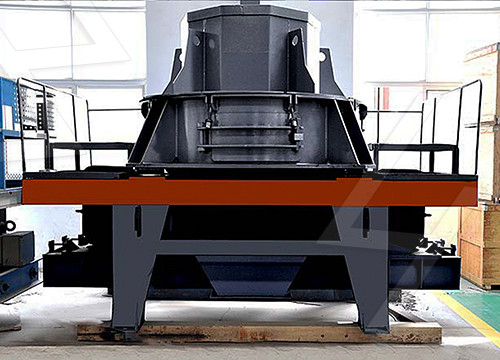

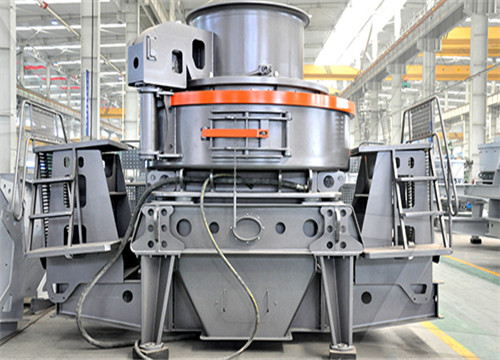

Grinder machine installation, use, maintenance and repair

The quality of grinder machine installation quality, the ability of machine is the key to normal work. Various types of grinder machine installation method and sequence of roughly the same. To ensure the smooth functioning of grinder machine and reducing the harm to the buildings, it must be installed on the weight of its 2.5 to 3 times the

Surface Grinder Basics How to Install a Grinding Wheel

2014年8月20日PSG 612 Surface Grinder: goo.gl/eaoTxWGrinder Wheels and Accessories: goo.gl/dic7ZDOne of our viewers asked for a demonstration

Parts and Functions of Grinding Machine

A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel’s

Commercial Espresso Machine Basic Plumbing Installation Requirements

Tighten the hose nut until the hose no longer swivels from the nut. Otherwise, purchase an optional adapter and run John Guest flexible tubing. We strongly suggest purchasing our BWT water treatment system for optimal protection. Size S, M, or V is good for the home. Larger sizes for office use.

Grinding and Polishing Buehler Metallography Equipment

GrindingPolishing for Metallographic Sample Preparation. The goal of the grinding and polishing steps is to prepare a final polished specimen that is free of deformation and suitable for analysis. This can be achieved in multiple ways depending on the overall goals of the lab. Whether a lab is looking for the quickest overall process, the

Reliability Modeling and Evaluation Method of CNC Grinding Machine

The CNC (computer numerical control) grinding machine tool is widely used in automotive, aircraft, and other industries to grind precise parts as the last process, and its reliability has an important influence on the processing quality and production efficiency. At present, high-performance CNC machine tools require reliability design.

Reliability Modeling and Evaluation Method of CNC

2018年12月21日grinding machine, and the probability density function of the whole machine can be fitted by the Appl. Sci. 2019,9,14 12 of 15 method in Section 2,as shown below .

Total Guide to CNC Jigs, Fixtures, and Workholding

Just align the plate to the sub-plate (which has the Receiver Bushings and is mounted to the table), drop the Ball Lock Shanks into the hole, twist the bolt on top of the Ball Lock Shank, and you are done. Twisting four bolts and

Basics of centerless grinding Cutting Tool Engineering

2016年12月1日520-548-7328. [email protected]. Kip Hanson is a contributing editor for Cutting Tool Engineering magazine. Contact him by phone at (520) 548-7328 or via e-mail at [email protected]. Ralf Schürl,

Workholding for Cylindrical Grinding Canadian Metalworking

2011年8月16日In the case of the chuck and collet, blanks have to be preground using centerless grinding. The more accurate of the two methods uses a four-jaw chuck. Each workpiece then can be indicated to precisely align the centerline of the part with the centerline of the chuck and spindle assembly.

Machining 101: What is Grinding? Modern Machine Shop

2021年7月3日On its surface, grinding seems simple: a machine takes a rotating tool (usually a wheel) with abrasive grains and applies it to a workpiece’s surface to remove material. Each grain is its own miniature cutting tool, and as grains dull, they tear from the tool and make new, sharp grains prominent.

Centerless Grinding an overview ScienceDirect Topics

Centerless Grinding Machines. In centerless grinding, the workpiece is held between two grinding wheels, rotating in the same direction at different speeds. One grinding wheel is on a fixed axis and rotates so that the force applied to the workpiece is directed downward. This wheel usually performs the grinding action by having a higher linear

Bench Grinder Basics You Need to Know — The

2018年10月2日To avoid ruining the edge of a tool by overheating, keep water nearby to cool the tool. A good technique is to move the tool once across the bench grinder for no more than a few seconds. Then dip it in

Chapter 5: Surface Grinder Manufacturing Processes

5. Move the grinding wheel down using the vertical table handwheel until it barely makes contact with the dresser. 6. Turn the machine off after making contact with the dresser. 7. Turn the machine on again. While the wheel

Grinder machine installation, use, maintenance and repair

The quality of grinder machine installation quality, the ability of machine is the key to normal work. Various types of grinder machine installation method and sequence of roughly the same. To ensure the smooth functioning of grinder machine and reducing the harm to the buildings, it must be installed on the weight of its 2.5 to 3 times the

Surface Grinder Basics How to Install a Grinding Wheel

2014年8月20日PSG 612 Surface Grinder: goo.gl/eaoTxWGrinder Wheels and Accessories: goo.gl/dic7ZDOne of our viewers asked for a demonstration

Grinding and Polishing Buehler Metallography Equipment

GrindingPolishing for Metallographic Sample Preparation. The goal of the grinding and polishing steps is to prepare a final polished specimen that is free of deformation and suitable for analysis. This can be achieved in multiple ways depending on the overall goals of the lab. Whether a lab is looking for the quickest overall process, the

Parts and Functions of Grinding Machine

Grinding machines or grinders are devices that are used to grind workpieces. This produces a smooth finish on the flat surface. The grinding wheel is used in grinding machines for cutting. The grinding wheel is

Reliability Modeling and Evaluation Method of CNC

How to determine subsystem’s reliability and evaluate the whole machine’s reliability of the CNC (computer numerical control) grinding machine tool is important for reliability design and promotion.

Reliability Modeling and Evaluation Method of CNC

2018年12月21日grinding machine, and the probability density function of the whole machine can be fitted by the Appl. Sci. 2019,9,14 12 of 15 method in Section 2,as shown below .

Total Guide to CNC Jigs, Fixtures, and Workholding

– The method of locating and securing that workholding device to your machine. This includes the ubiquitous T-Slots but goes on to include modular fixture plates, 4th axis solutions, and much more. We’ll go

Machines Free Full-Text Research on Generating Gear Grinding

2022年12月12日Yoshino et al. investigated the effects of grinding machine positioning errors (center distance error, grinding wheel inclination error, and grinding wheel axial position error, etc.) on the helical gear tooth profile, and they proposed an interactive analysis method to compensate for the grinding errors by eliminating more than two

Basics of centerless grinding Cutting Tool Engineering

2016年12月1日520-548-7328. [email protected]. Kip Hanson is a contributing editor for Cutting Tool Engineering magazine. Contact him by phone at (520) 548-7328 or via e-mail at [email protected]. Ralf Schürl,

Centerless Grinding an overview ScienceDirect Topics

Centerless Grinding Machines. In centerless grinding, the workpiece is held between two grinding wheels, rotating in the same direction at different speeds. One grinding wheel is on a fixed axis and rotates so that the force applied to the workpiece is directed downward. This wheel usually performs the grinding action by having a higher linear

Making the Right Shaft Connections Machine Design

2000年8月1日Securing a belt pulley to a drive shaft often seems like such a routine task, that engineers and mechanics can easily overlook some of the selection and installation factors required to achieve a

Continuous generating grinding method for beveloid gears

2022年3月7日Continuous generating grinding has become an important gear processing method owing to its high efficiency and precision. In this study, an adaptive design model is proposed for the continuous generation of beveloid gears in common gear grinding machines. Based on this model, a method for determining the installation position and